Polysoude

60 years of state-of-the-art orbital tube & pipe welding

Quality without

compromise

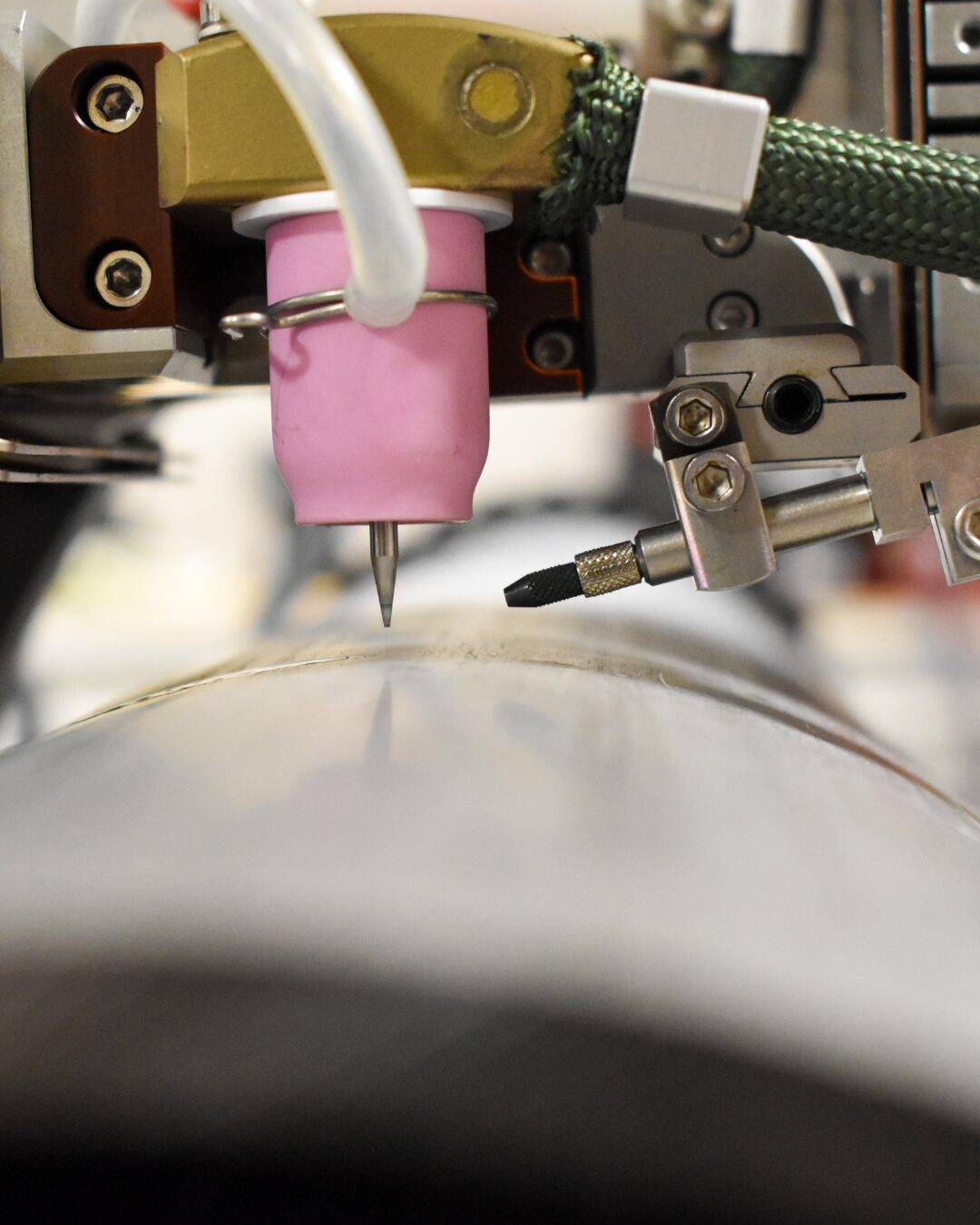

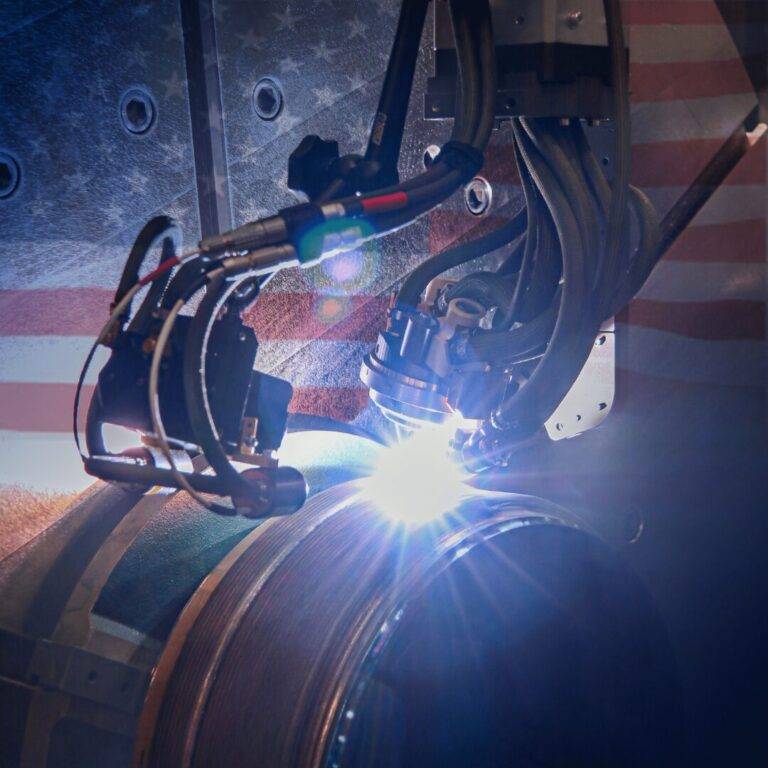

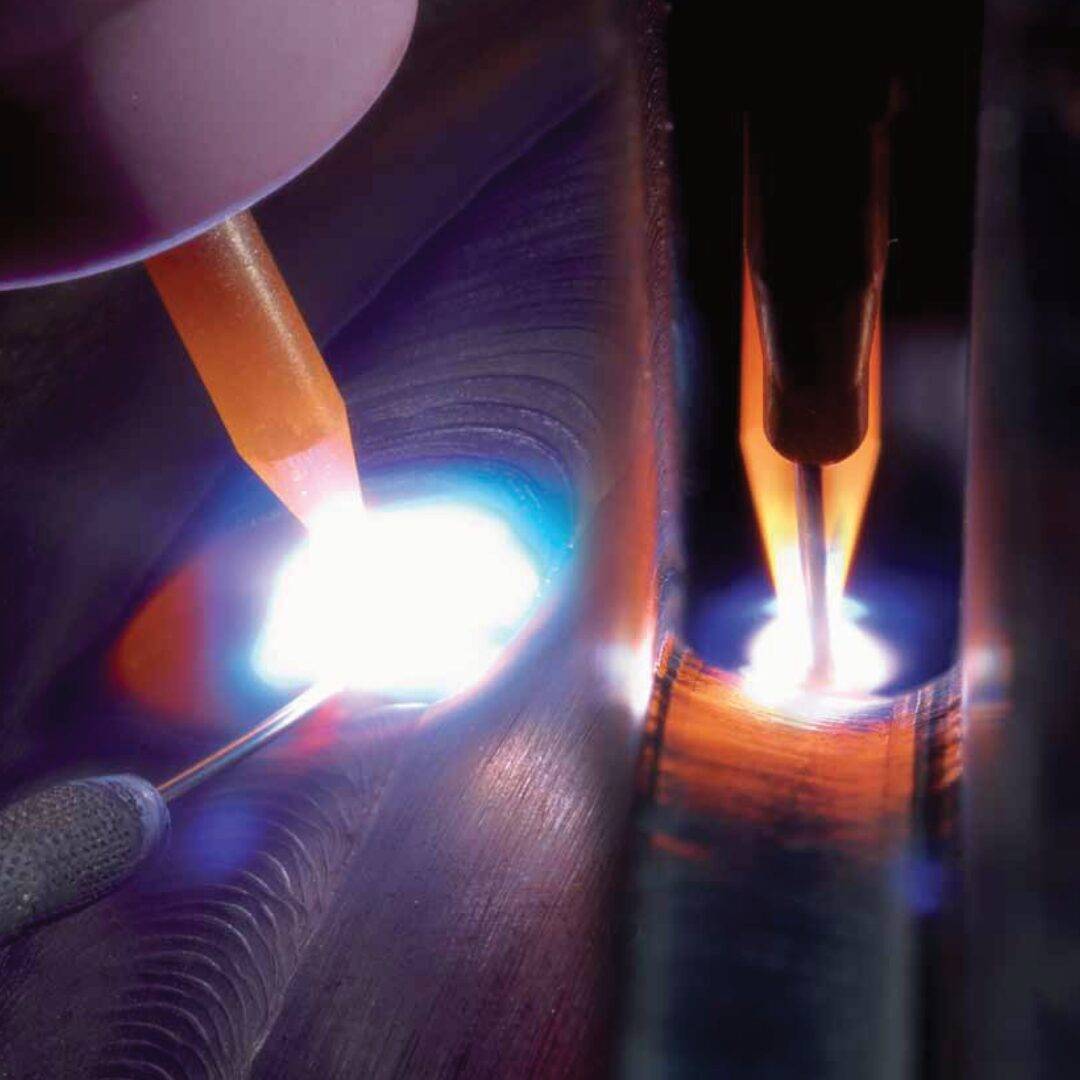

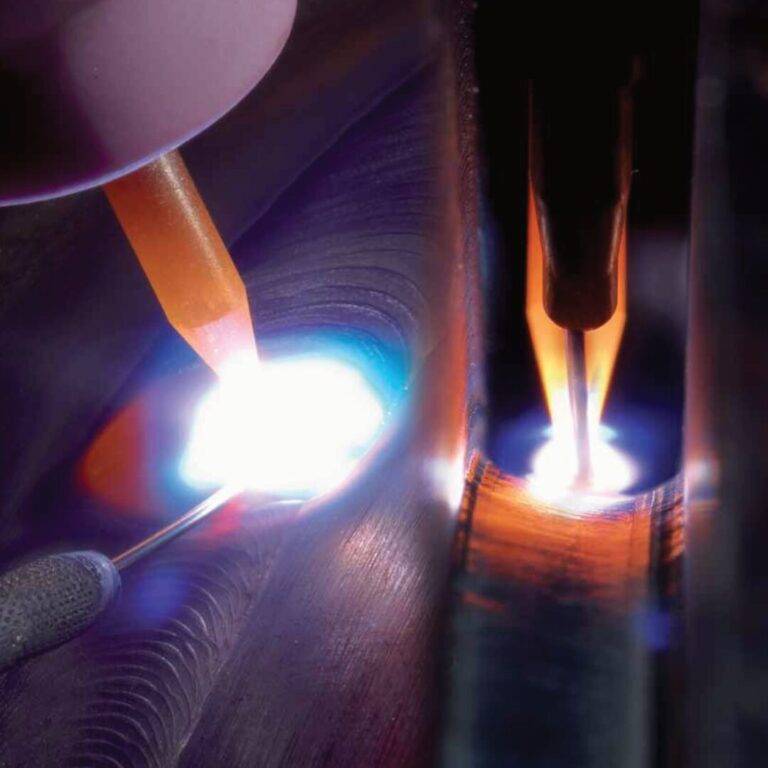

For the past 60 years, Polysoude has been revolutionizing the orbital welding industry. Specializing in the design and manufacturing of high-quality orbital welding equipment and automated solutions for TIG welding and TIG weld overlay/cladding, Polysoude believes in quality without compromise.

Polysoude strives to provide the best equipment for every solution, constantly innovating and improving their product line to meet the needs of their customers. They believe in a “Zero Risk/Zero Defects” mindset, expressing their commitment to perfection and prevention, not correction. Polysoude holds themselves to the highest standard, ensuring that everything they do is done with unmatched precision, care, and to the utmost degree of quality.

Quality without

compromise

For the past 60 years, Polysoude has been revolutionizing the orbital welding industry. Specializing in the design and manufacturing of high-quality orbital welding equipment and automated solutions for TIG welding and TIG weld overlay/cladding, Polysoude believes in quality without compromise.

Polysoude strives to provide the best equipment for every solution, constantly innovating and improving their product line to meet the needs of their customers. They believe in a “Zero Risk/Zero Defects” mindset, expressing their commitment to perfection and prevention, not correction. Polysoude holds themselves to the highest standard, ensuring that everything they do is done with unmatched precision, care, and to the utmost degree of quality.

power in

partnership

Equipment for all

Applications

Equipment for all

Applications

Equipment for all

Applications

polysoude in action

Tube Equipment

Power Supplies

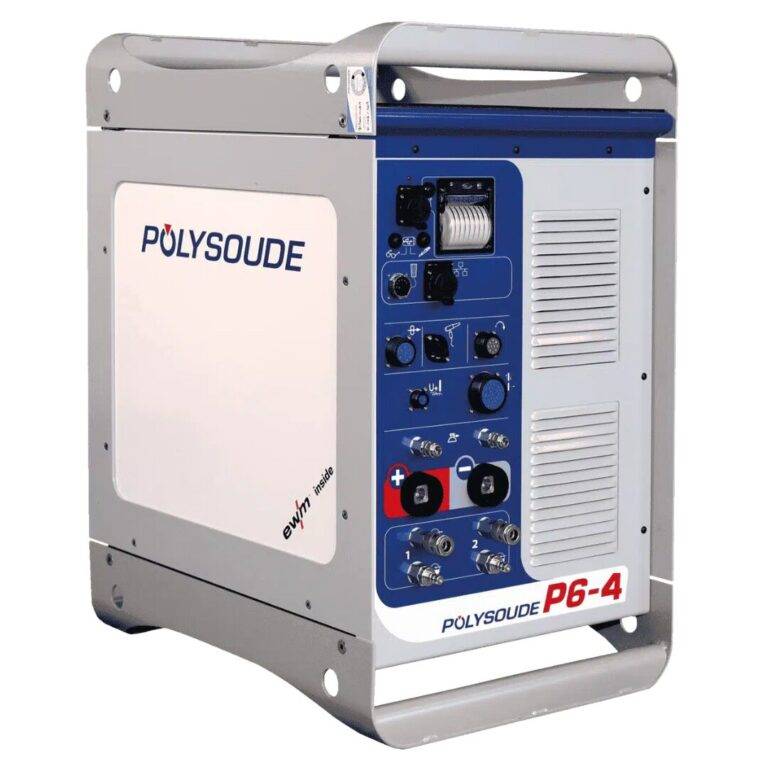

P4 Power Supply

- Available in 115A to 230A

- TIG, constant or pulsed, with/without filler wire

P4 Power Supply

- Available in 115A to 230A

- TIG, constant or pulsed, with/without filler wire

Closed Weld Heads

MW Weld Head

- Tube Ranges: 1/4″ to 6.625″

- Integrated remote control

- Closed-loop water cooling

UHP Weld Head

- Tube Ranges: 1/16″ to 1″

- Quick change handle for UHP 250, 500, and 1000

- Ultra-compact design for maximum accessibility

MW Weld Head

- Tube Ranges: 1/4″ to 6.625″

- Integrated remote control

- Closed-loop water cooling

UHP Weld Head

- Tube Ranges: 1/16″ to 1″

- Quick change handle for UHP 250, 500, & 1000

- Ultra-compact design for maximum accessibility

Pipe Equipment

Power Supplies

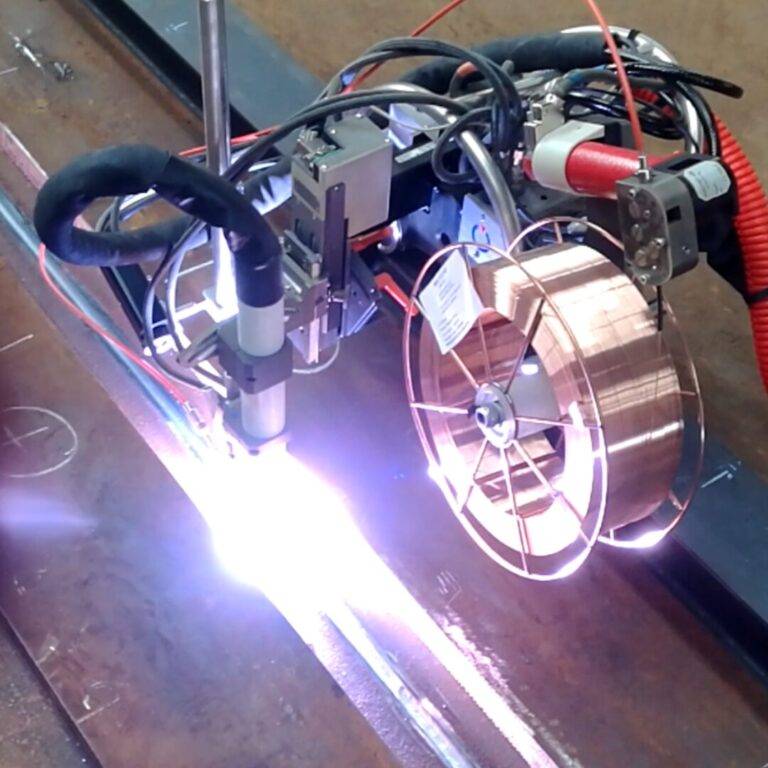

Carriage type Weld Heads

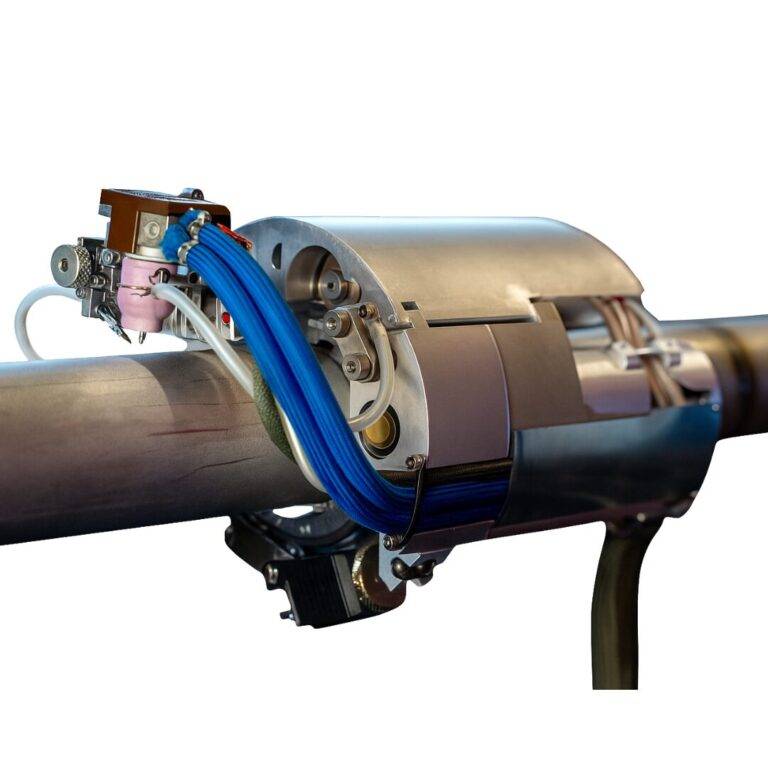

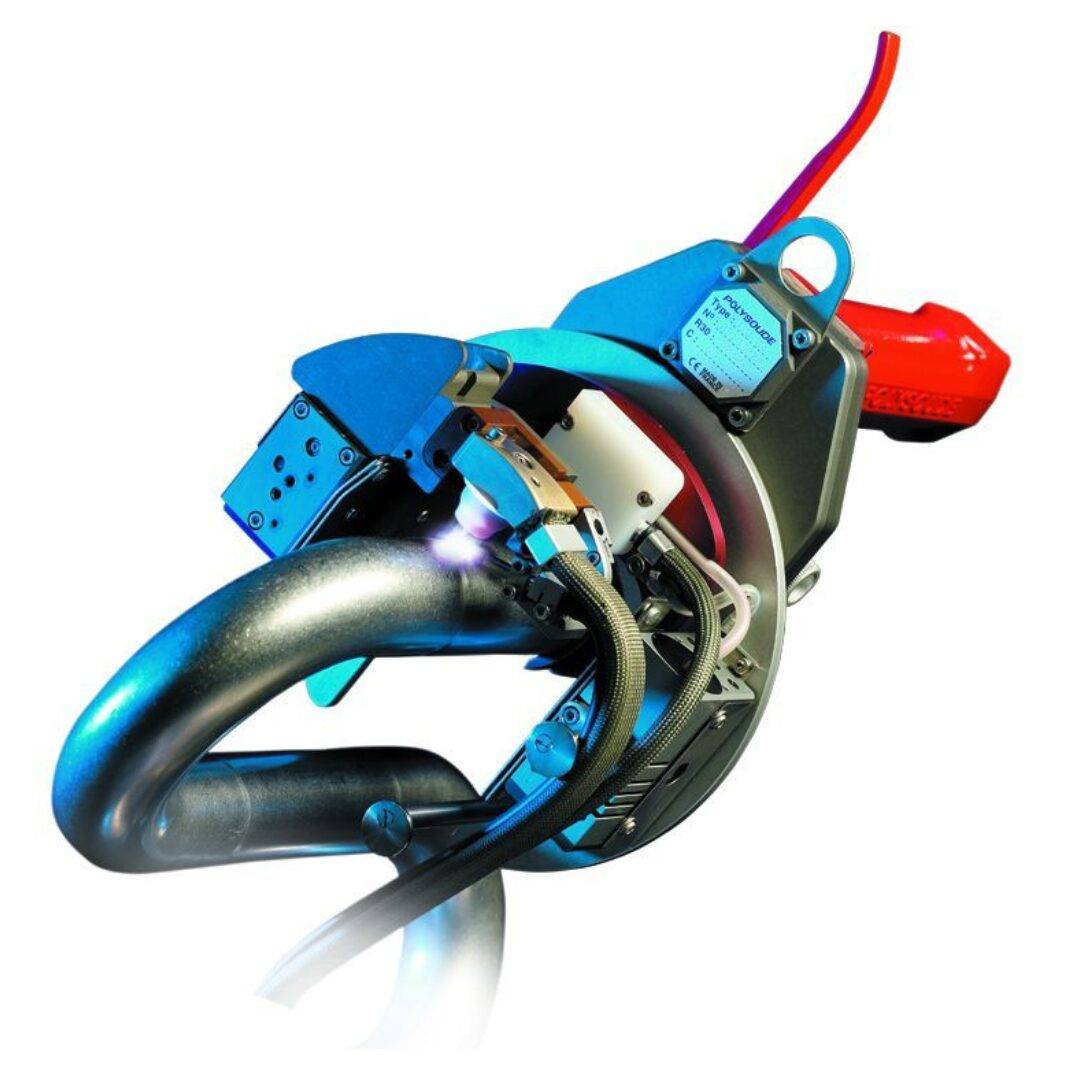

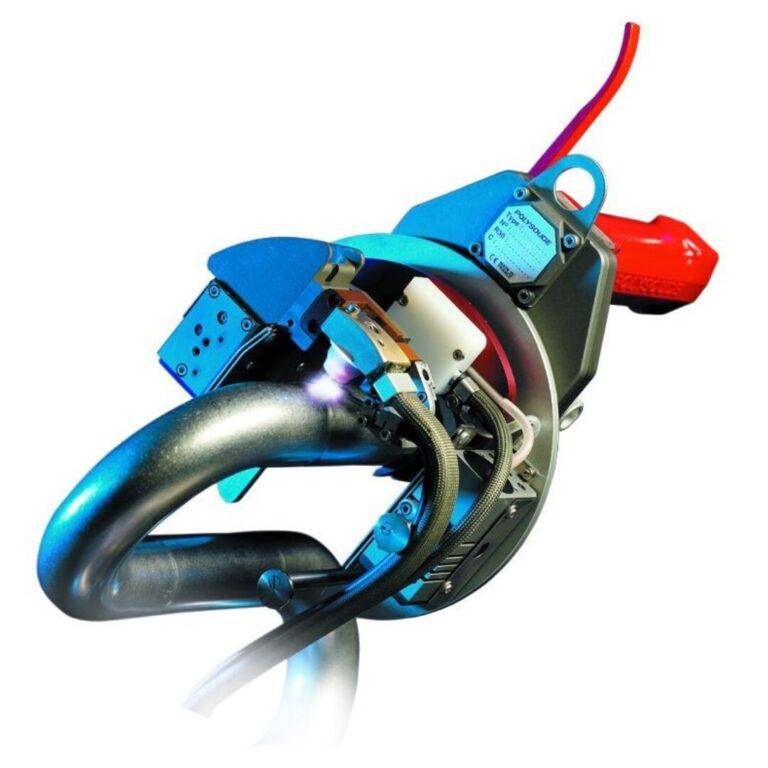

Polycar 30

- OD Range: 1.315″ to 6.625″

- Max travel speed: 19.7 in/min

- AVC Tilt, ID Welding, & more configurations

Polycar 51

- OD Range: 2″ to 14″

- Max travel speed: 20 in/min

- Ultra compact; only 2″ radial clearance needed

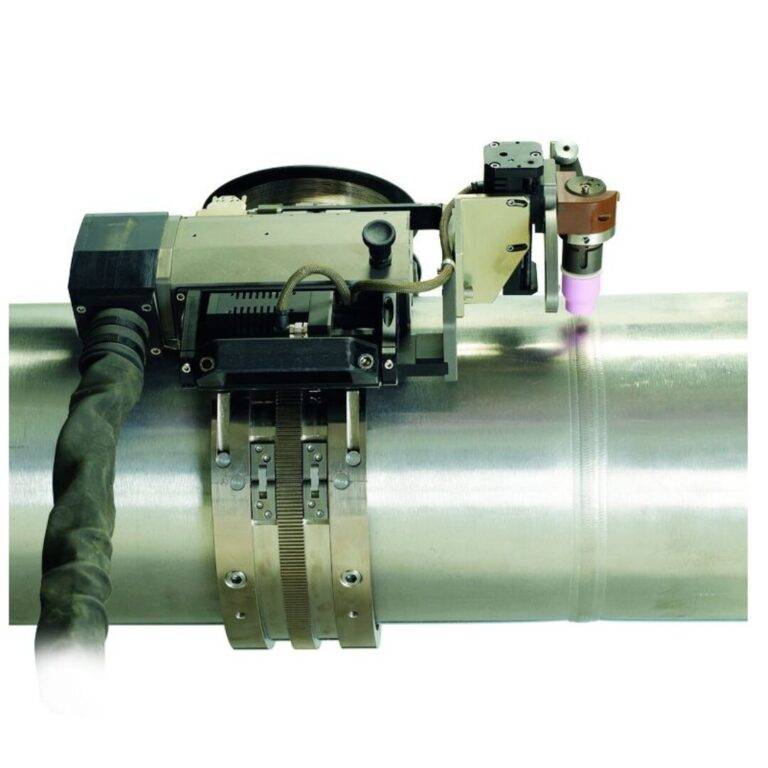

Polycar 60

- OD Range: 6.625″ OD Pipe and up

- CW, HW, & LP

- AVC & OSC for multi-pass

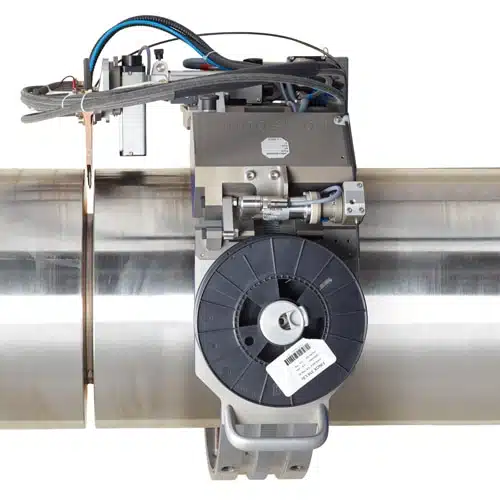

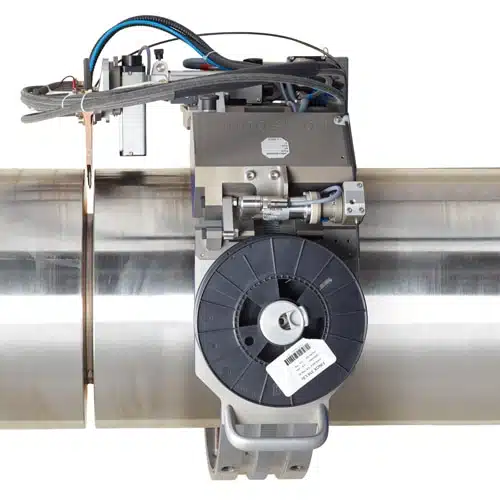

Polycar 60 PLC

- OD Range: 6.625″ OD Pipe and up

- Maximum wall thickness: 3.9″

- Integrated wire feeder

Polycar 30

- OD Range: 1.315″ to 6.625″ OD Pipe

- Max travel speed: 19.7 in/min

- AVC Tilt, ID Welding, & more configurations

Polycar 51

- OD Range: 2″ to 14″

- Max travel speed: 20 in/min

- Only 2″ radial clearance needed

Polycar 60

- OD Range: 6.625″ OD Pipe and up

- CW, HW, & LP

- AVC & OSC for multi-pass

Polycar 60 PLC

- OD Range: 6.625″ OD Pipe and up

- Maximum wall thickness: 3.9″

- Integrated wire feeder

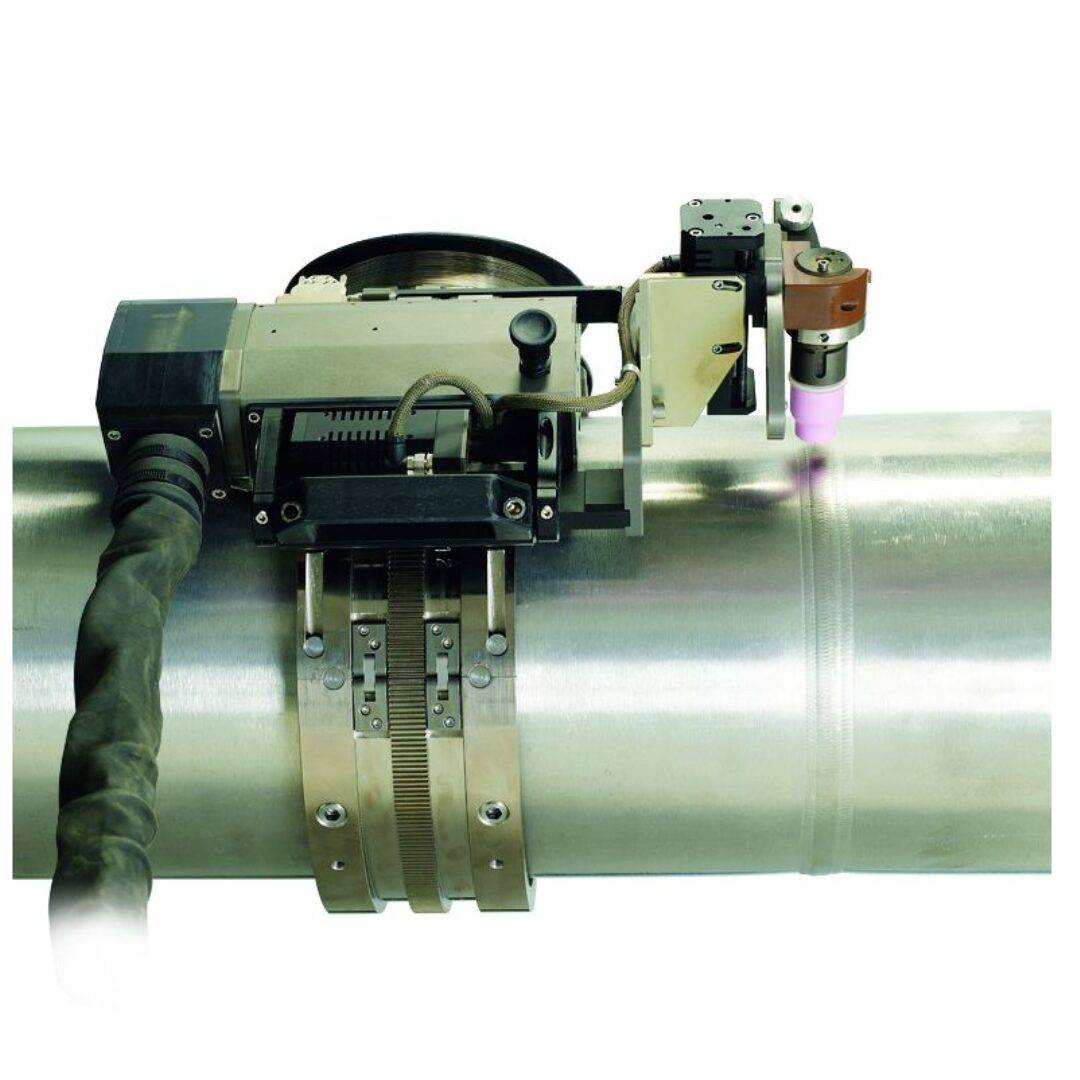

Open Weld Heads

MU IV Weld head

- O.D. Range: 5/16″ – 10″

- Two interchangeable clamping systems, C & P

- Integrated on-board wire feeder

MU IV 195 HW weld head

- O.D. Diameter Range: 3″ to 7.7″

- Integrated wire feeder

- Quick clamping system

MU IV Weld head

- O.D. Range: 5/16″ – 10″

- Two interchangeable clamping systems, C & P

- Integrated on-board wire feeder

MU IV 195 HW weld head

- O.D. Diameter Range: 3″ to 7.7″

- Integrated wire feeder

- Quick clamping system

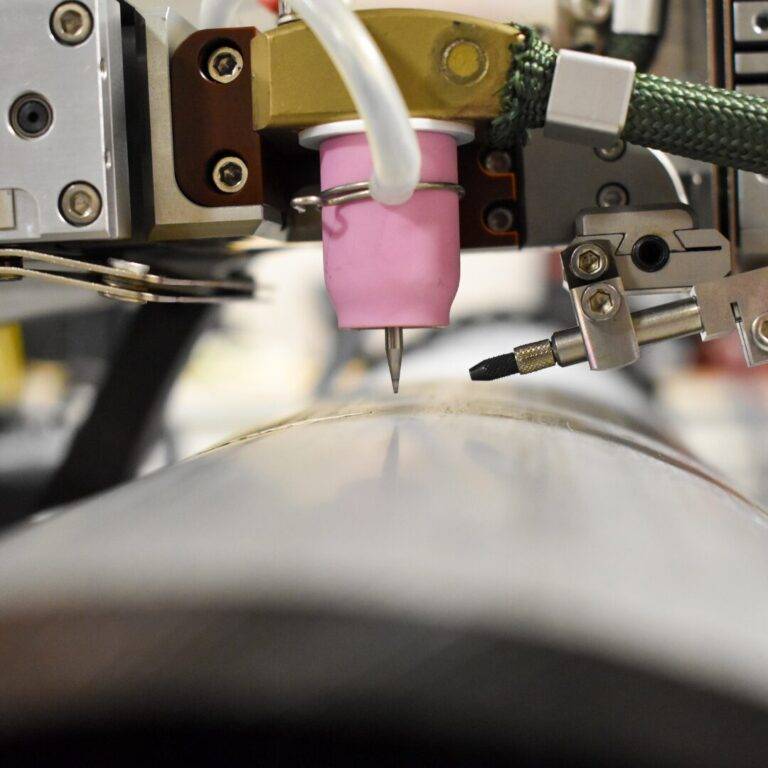

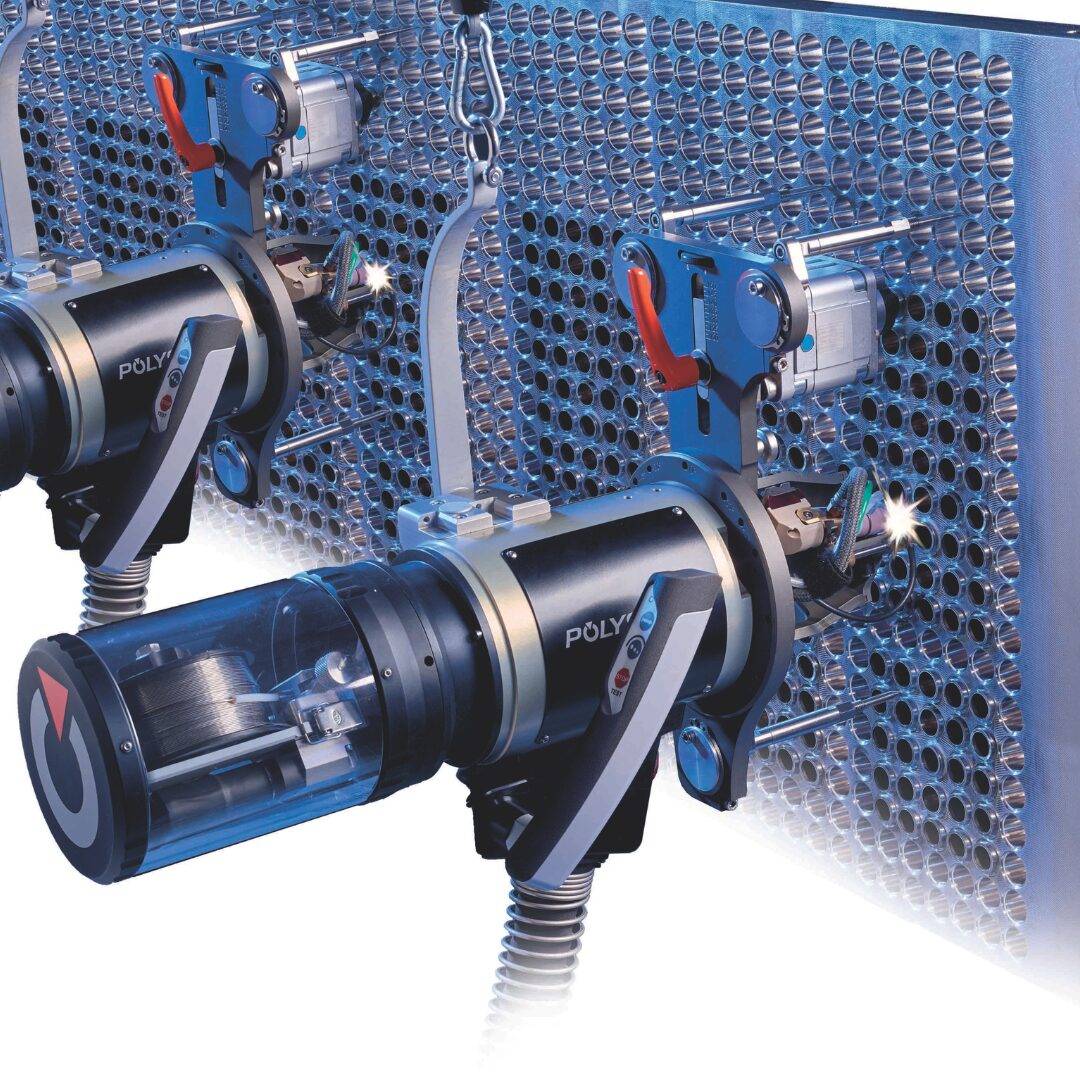

Tube-to-tubesheet Weld Heads

TS 34 Tubesheet wh

- Diameter Range: 0.315″ I.D. – 2.95″ O.D.

- Flush, Recessed, Low Protruding, Protruding, Internal Bore, Back Plate/Header Box

ts 8/75 tubesheet wh

- Diameter Range: 0.39″ I.D. – 1.33″ O.D.

- Tube Joint Designs: Flush, Recessed, Protruding, Internal Bore Welding

TS 34 Tubesheet wh

- Diameter Range: 0.315″ I.D. – 2.95″ O.D.

- Flush, Recessed, Low Protruding, Protruding, Internal Bore, Back Plate/Header Box

ts 8/75 tubesheet wh

- Diameter Range: 0.39″ I.D. – 1.33″ O.D.

- Tube Joint Designs: Flush, Recessed, Protruding, Internal Bore Welding

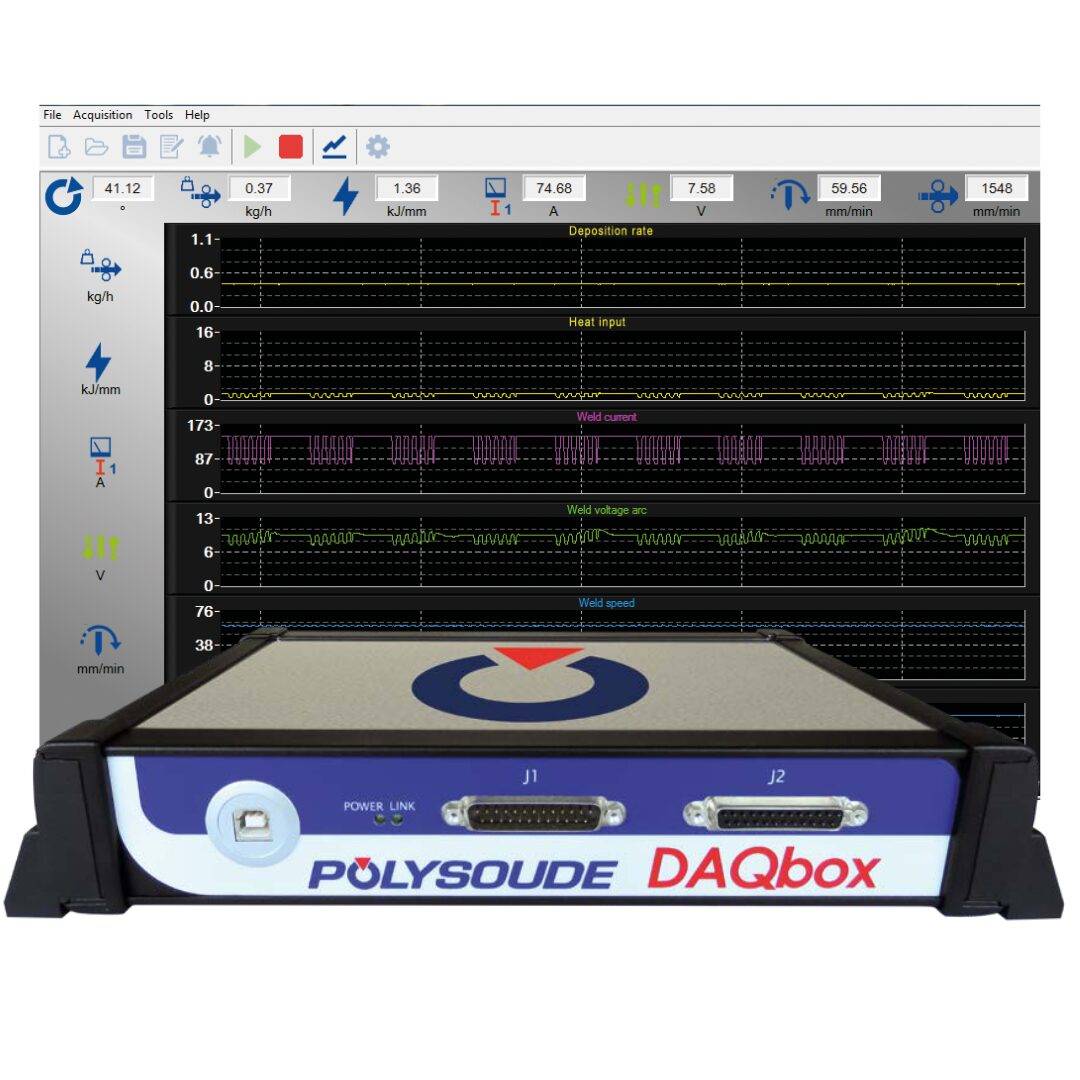

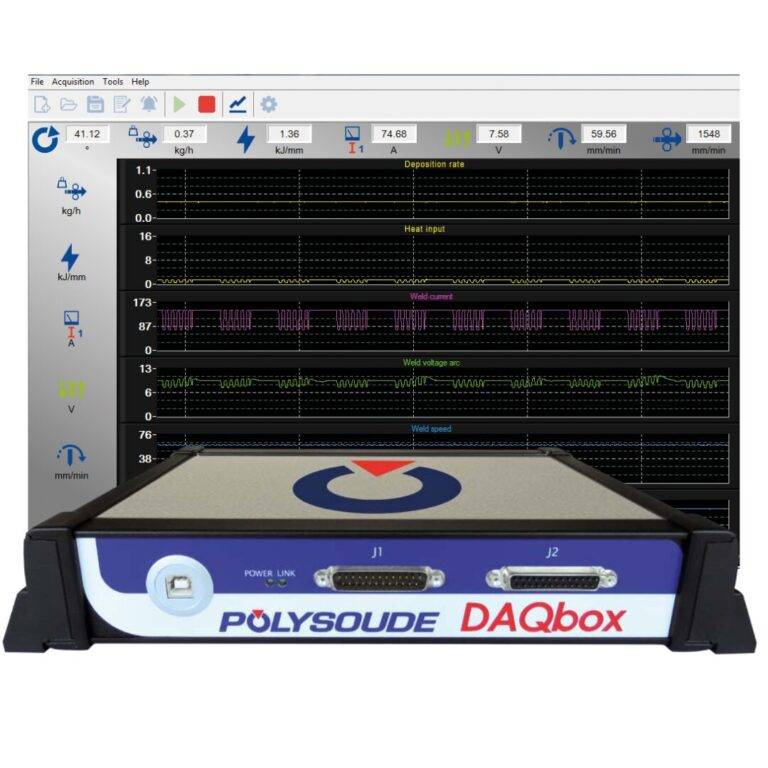

Accessories

Polyview

- Video Monitoring & Recording System

- Full-color, high-resolution video

Polyview

- Video Monitoring & Recording System

- Full-color, high-resolution video