High-Precision Orbital Welding for Tube-to-Tube & Tube-to-Fitting Applications

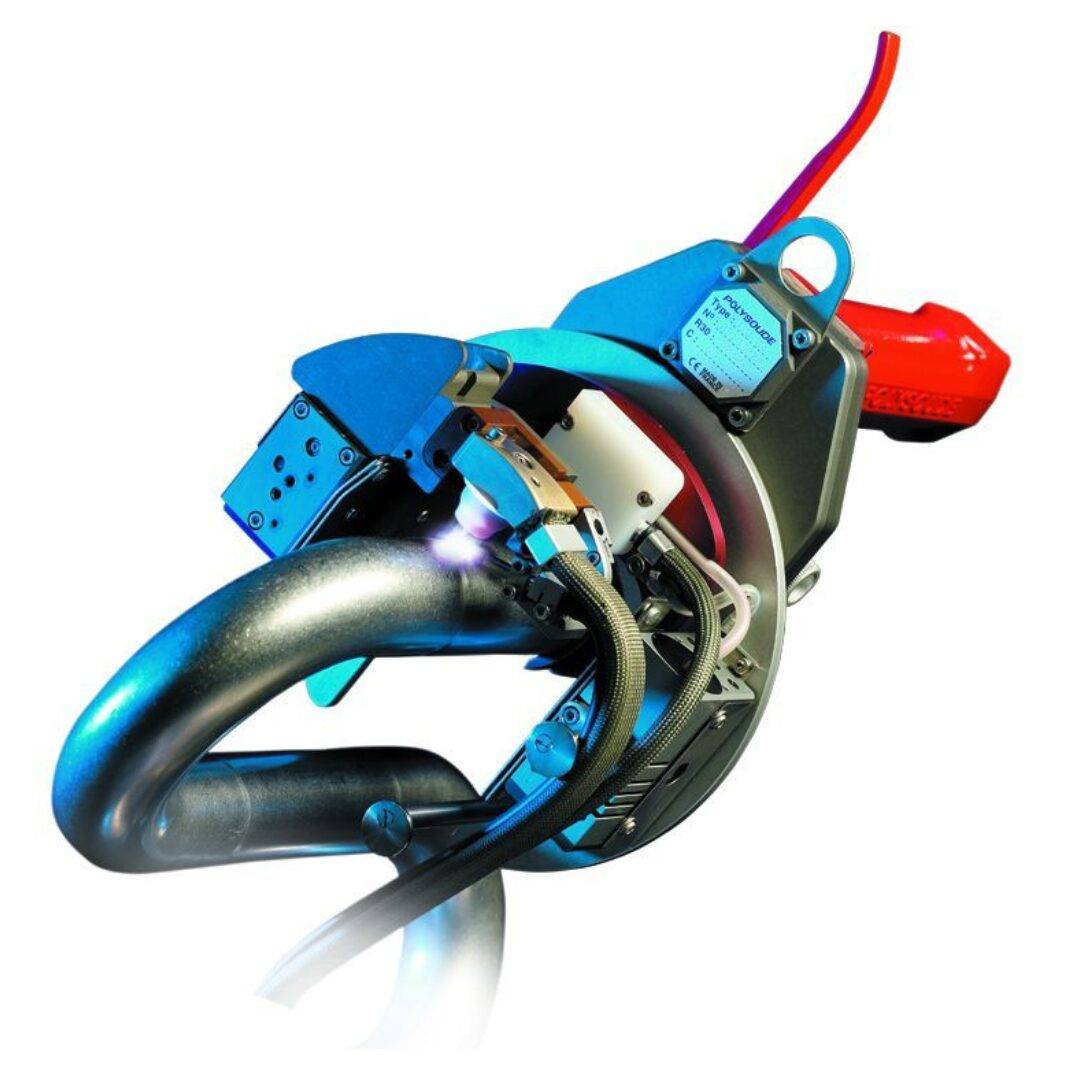

The Polysoude MU IV is a modular, open-type orbital welding head engineered for the most demanding tube and pipe fabrication environments. Designed for TIG welding with or without filler wire, as well as AVC and OSC configurations, the MU IV delivers superior weld quality, repeatability, and productivity across stainless steel and high-alloy applications.

Backed by more than 60 years of Polysoude welding expertise, the MU IV combines advanced control systems, precision mechanics, and robust construction — making it the ideal choice for high-purity, high-integrity welding work across industries such as pharmaceutical, biotech, food & beverage, chemical processing, aerospace, and energy.

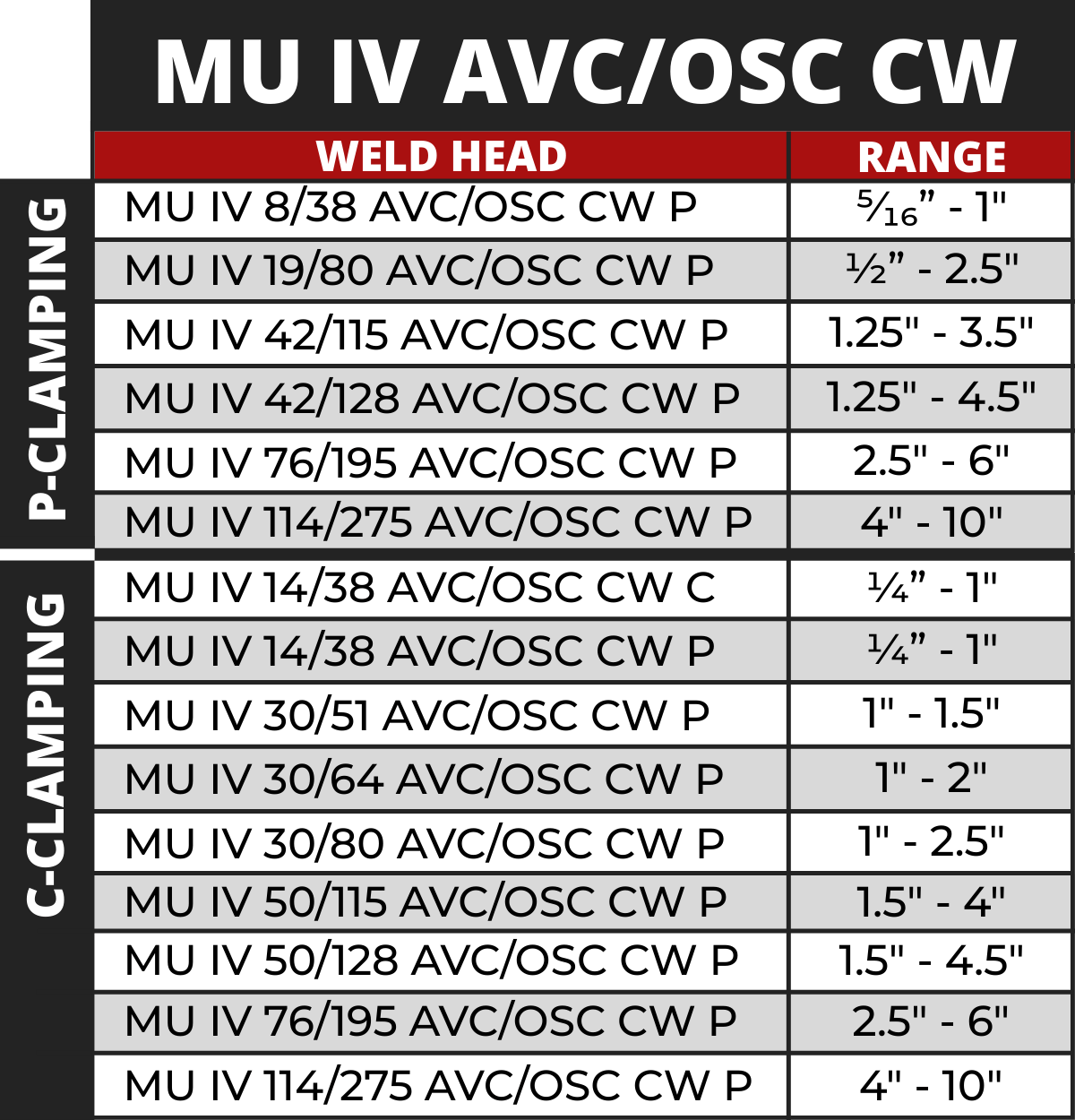

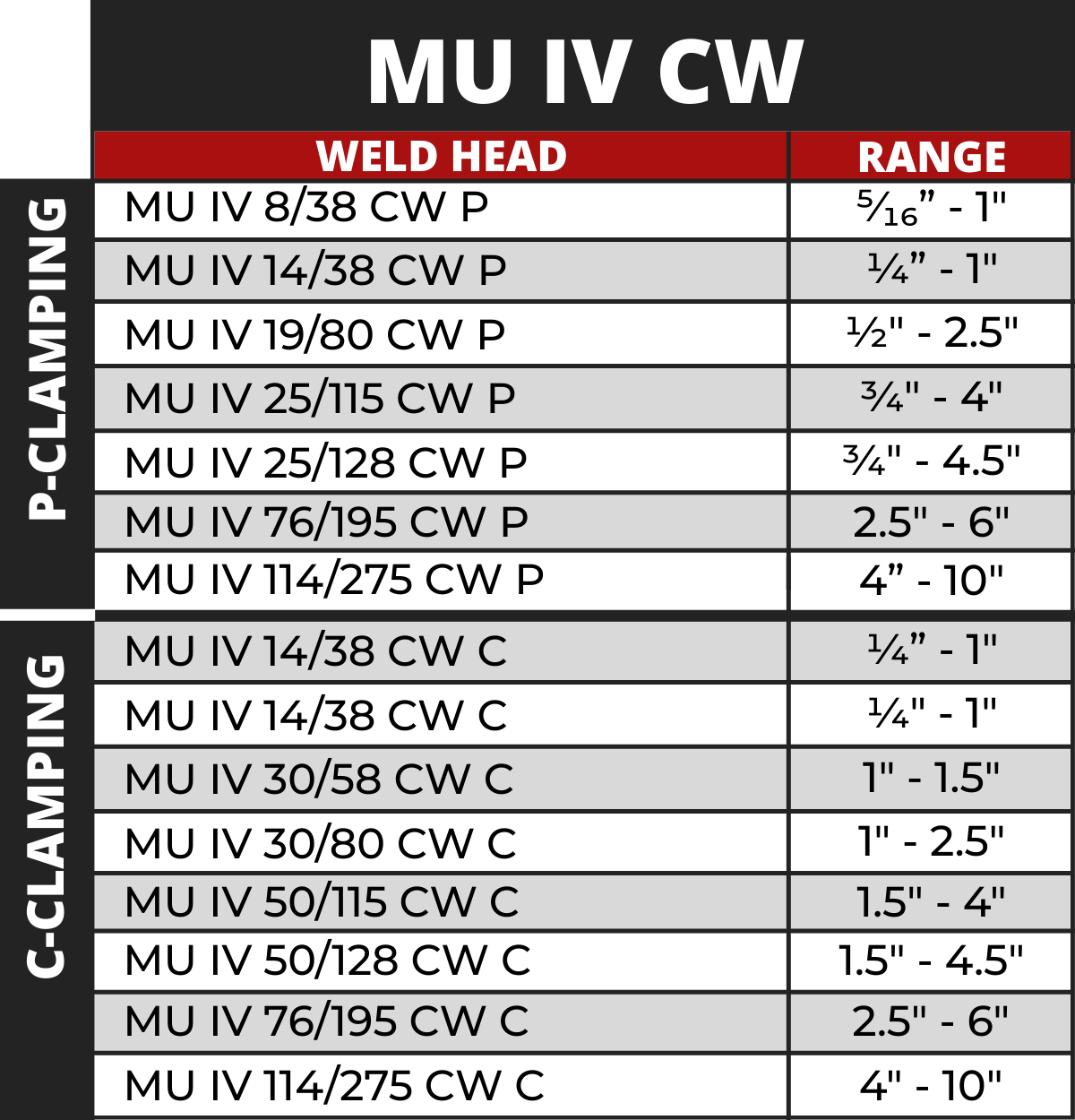

Two interchangeable clamping systems, C and P:

C-Clamping system (Shell Style)

– One set of shells per specific OD

– Ideal for precise, heavy-duty, production grade clamping

P-Clamping system (Chunk Style)

– Fully adjustable for the entire OD range

– Perfect for frequent diameter changes

Benefits and Features:

– Supports TIG welding, with or without filler wire

– Compatible with AVC and OSC for multi-pass welding

– Closed-loop regulation ensures constant or pulsed welding speed

– Encoder-based position control for highly repeatable welding programs

– Open head configuration optimized for tube-to-tube and tube-to-elbow joints

– Planetary drive system delivers smooth, constant torch rotation

– Water-cooled torch and gas lens ensure stable shielding and thermal control

– Integrated mechanical sensor maintains precise electrode-to-workpiece distance

– Two interchangeable clamping systems

– Integrated on-board wire feeder for 1.5 kg spools

– Includes 2-axis wire adjustment for perfect positioning