Advanced multipass tig welding for tubes and pipes

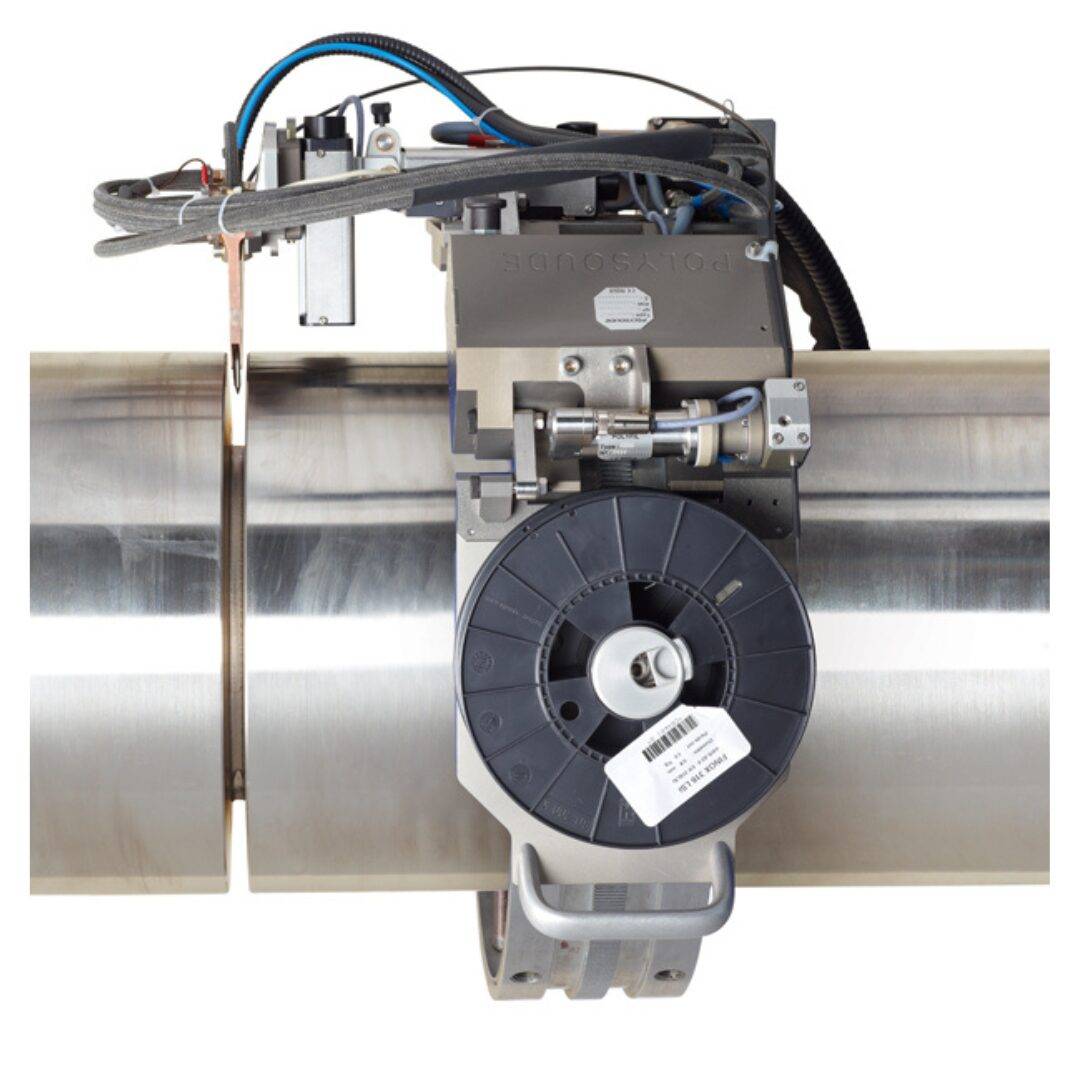

The POLYCAR 60 PLC is an advanced orbital TIG welding head engineered for high-precision, multipass welding of tubes and pipes—particularly ideal for medium and heavy wall thicknesses and nuclear primary loop circuits. Designed with durability, accessibility, and maximum productivity in mind, the POLYCAR 60 PLC combines sophisticated automation with rugged construction to achieve consistent, high-quality welds in demanding industrial environments.

This weld head delivers a comprehensive range of performance advantages, combining orbital TIG welding capability with both hot and cold wire options to ensure exceptional weld quality. Engineered for medium and heavy wall thicknesses, it excels in narrow gap applications up to 3.9″ (100 mm) groove depth while maintaining precision across all welding passes. The welding head travels effortlessly around the work piece using a pre-mounted guide ring, and its full-function design completes multi-pass welds with consistent results.

Built from high-temperature-resistant materials and equipped with closed loop water cooling, it supports demanding high-duty-cycle environments. Its slim, low-profile construction allows operation in areas with restricted radial or axial clearance, ensuring maximum flexibility and accessibility.

The POLYCAR 60 PLC delivers a comprehensive range of performance advantages, combining orbital TIG welding capability with both hot and cold wire options to ensure exceptional weld quality. Check out more of the benefits and features below:

Benefits and Features:

- Diameter range: 6.625″ (168 mm) OD Pipe and up

- Maximum wall thickness: 3.9″ (100 mm)

- Dual Torch System

- Narrow Gap Torch for root passes and filling

- Standard finishing torch with integrated camera

- Integrated wire feeder with 11 lbs (5 kg) spool

- Rotation clutch device for quick cable winding

- AVC and OSC for multi-pass welding of medium and heavy wall thickness

- Mechanical seam tracking