Ultra high purity orbital tig welding

Designed for industries where purity, precision, and repeatability are non-negotiable

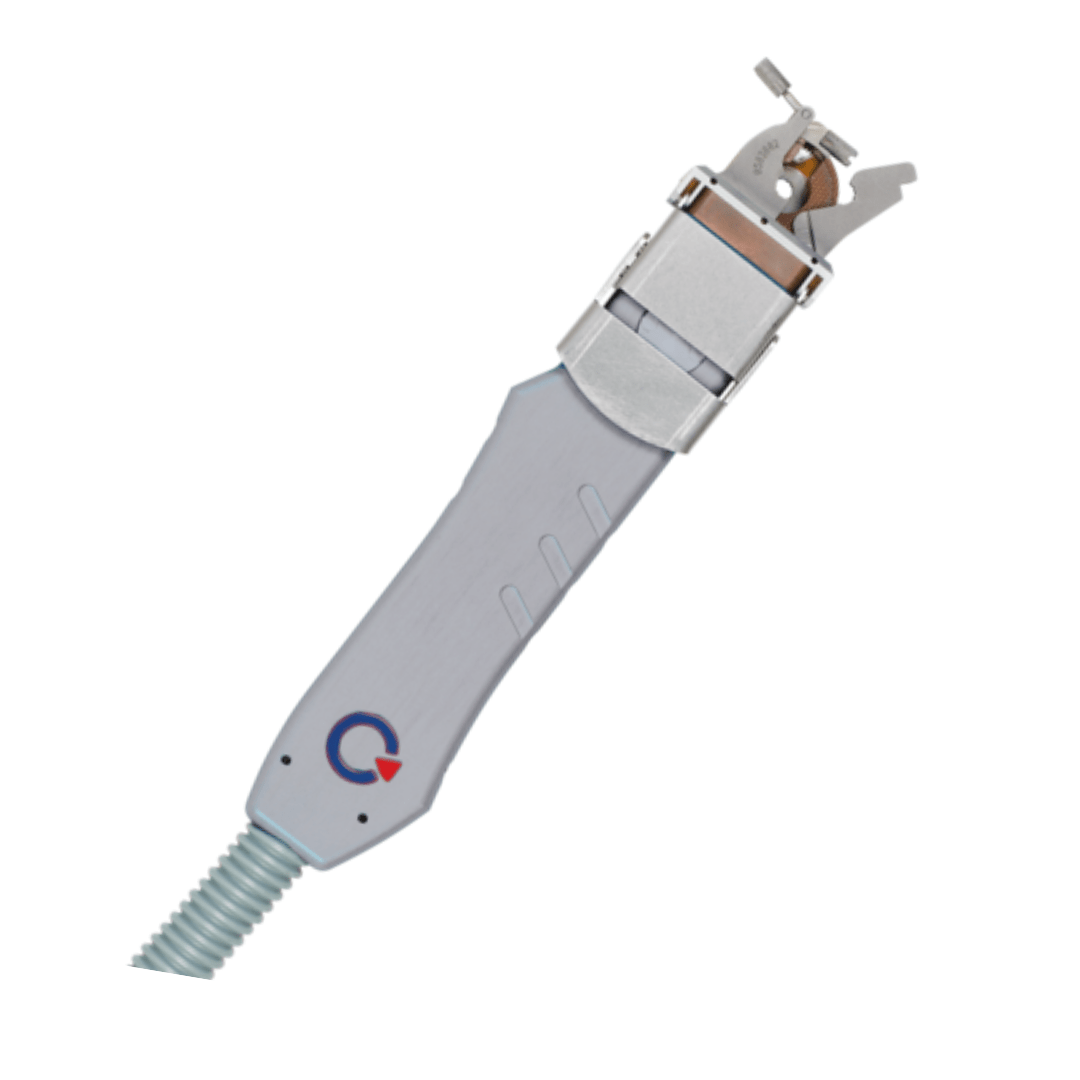

Polysoude’s UHP Closed Chamber Welding Heads are engineered for applications where exceptional cleanliness, high precision, and perfect repeatability are essential. Designed specifically for the demands of Ultra High Purity industries, these orbital TIG heads combine compact architecture, advanced gas management, and modular flexibility to deliver oxidation-free welds across a wide range of tube diameters.

Drawing from more than 60 years of expertise in orbital welding technology, Polysoude ensures that every model in the UHP range meets the rigorous standards required in semiconductor manufacturing, cleanroom environments, aerospace, nuclear, pharmaceutical, and food and beverage applications.

The UHP series is designed with an ultra-compact form factor, featuring reduced radial and axial dimensions that allow operators to weld effectively even in the tightest spaces. Precision is maintained through a highly efficient closed-loop regulation system that ensures a perfectly consistent welding speed, whether constant or pulsed, resulting in exceptional reproducibility. Thanks to its modular design, the system can be adapted to cover an extensive range of diameters, making it a versatile solution for diverse tube welding needs.

Each welding head also incorporates an adaptable clamping system that can be configured to match the geometry of the workpiece, ensuring secure positioning and outstanding accuracy. The closed chamber design, combined with a high-purity gas circuit, prevents particle emissions and oxidation, further guaranteeing the ultra-clean welds required in advanced manufacturing sectors.

The UHP range covers tube outside diameters from as small as 1/16″ or 1.6 mm (UHP 250-2) to as large as 1″ or 25.4 mm (UHP 1000), with a standard cable length of 18″ (5.5 meters) for all models. Each welding head features carefully optimized dimensions to offer the best possible access and clamping capability, even in space-restricted environments.

The UHP series delivers oxidation-free welds through its clean, controlled gas environment and high-stability chamber design. The system’s engineering prioritizes simplicity and operational efficiency, resulting in reduced maintenance requirements and a lower overall cost of ownership. With cassette and fixture block technologies, operators can achieve consistently high-quality orbital welds, even when managing complex geometries or micro-fittings. These features, combined with Polysoude’s decades of proven expertise in orbital welding, ensure reliable and repeatable performance throughout every weld cycle.

UHP Weld Heads

UHP 250

- 1/16″ – 1/4″

- Slim & ultra-compact for short stick-out fittings and tight-space applications

UHP 500

- 1/8″ – 1/2″

- Balance of size and performance — ideal for flexible orbital tube welding

UHP 1000

- 1/4″ – 1″

- High-performance chamber design with optimized geometry for larger diameters

UHP 625

- 1/8″ – 11/16″

- Features advanced fixture blocks, reversible hook, and ergonomic integrated controls

Benefits and Features:

– Quick change handle to easily switch between interchangeable UHP 250, 500, and 1000 modules

– Ultra-compact design with reduced radial and axial dimensions for maximum accessibility

– Adaptable clamping system with reversible hooks, cassettes, and fixture blocks to suit various tube geometries

– High-purity closed gas circuit to prevent oxidation and particle emission

– Closed-loop speed regulation for precise, constant, or pulsed welding control

– Encoder-based position control for accurate program execution

– Cleanroom-compatible design with heat-resistant construction for demanding applications

– Ergonomic operation with integrated remote control on the UHP 625 model

– Compatibility with a full suite of Polysoude Welding Stations

– Delivers oxidation-free, contamination-free orbital welds

– Provides highly repeatable, high-quality weld results across a wide tube diameter range