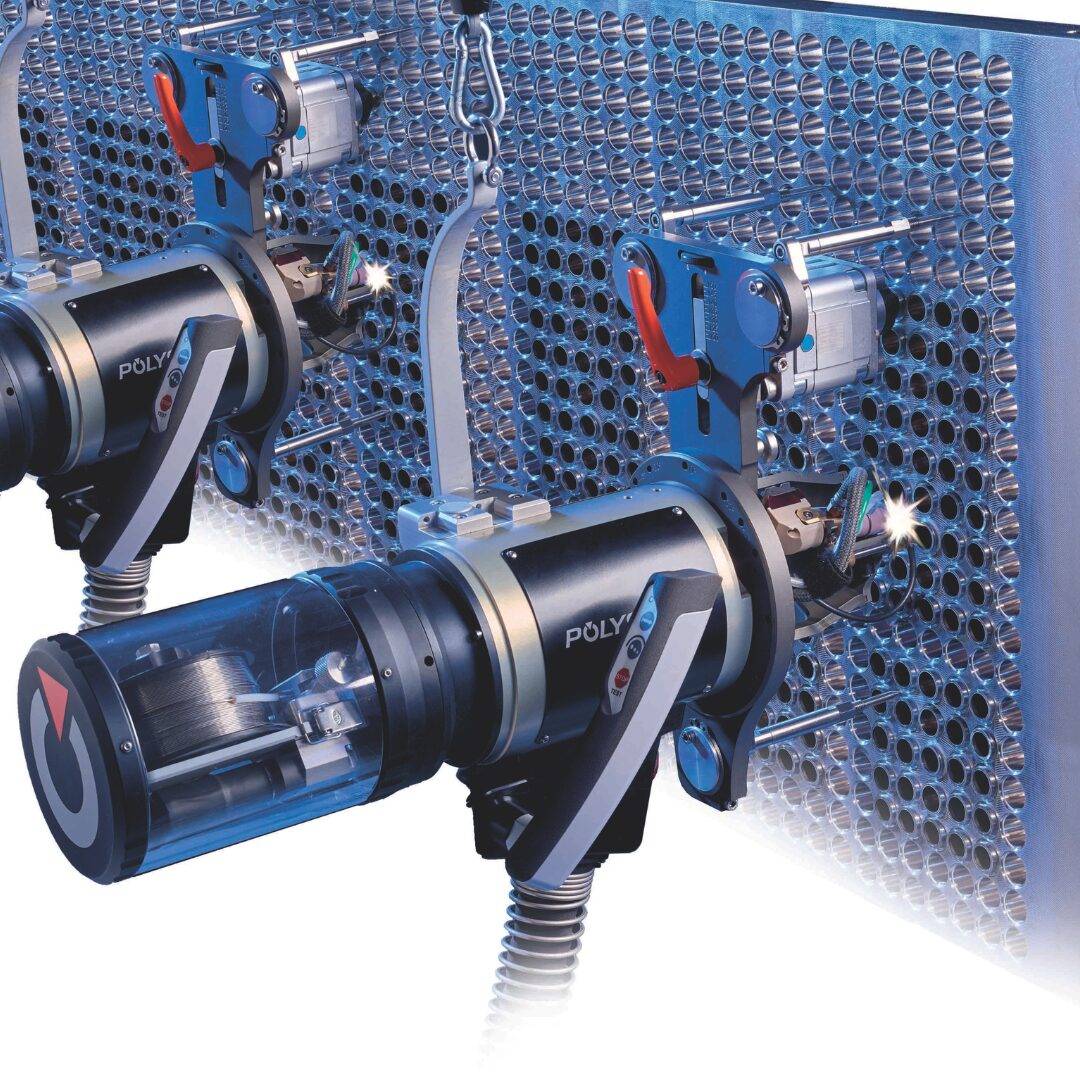

Open welding head for tube-to-tubesheet joints

The Polysoude TS 8/75 is a high-precision open welding head engineered specifically for TIG welding of tube-to-tubesheet joints. Designed for heat exchangers, boilers, condensers, and other industrial assemblies, it combines advanced automation, ergonomic handling, and premium materials to deliver exceptional performance and repeatable weld quality. Its ability to operate with or without filler wire and the inclusion of Arc Voltage Control make it a versatile solution for a wide range of welding applications.

This welding head is adaptable to virtually all common tube-to-tubesheet joint types. It supports protruding, flush, and recessed tube welding, as well as internal bore welding and back plate or header box configurations, including both flush and recessed variants. For applications involving low-protruding tubes, dedicated pneumatic clamping and centering tooling is available. The versatility of the TS 8/75 allows fabricators to take on a broad range of tubesheet configurations using a single, modular welding system.

The TS 8/75 is built for maximum operator comfort and efficiency. Its lightweight, compact construction and integrated handle controls allow operators to maneuver the head easily, even in dense tubesheet environments. Productivity is significantly increased because multiple welding heads can be used simultaneously, supported by the integrated pneumatic clamping system.

Operators benefit from simplified adjustments, especially for wire feeding and support feet, enabling rapid training and intuitive setup. The system’s on-board wire feeder—available in fixed or rotating configurations—ensures filler wire is supplied with exceptional consistency, eliminating variations in feeding speed or placement.

Benefits and Features:

- Adapts to nearly all common geometries: Protruding tube welding, flush tube welding, recessed welding, internal bore welding, back plate / header box welding (flushed & recessed), low-protruding tubes (optional tooling available)

- TIG welding with or without filler wire

- Closed-loop regulation for precise, constant, or pulsed welding speeds

- Unique rotating collector for welding current, shielding gas, and liquid cooling

- Integrated remote control for clamping and welding

- Optional centering shafts and mandrels for special tube sizes

- Return-to-home function returns electrode to initial position automatically

- Tube Compatibility:

- Minimum tube I.D.: 0.31″ (8mm)

- Maximum tube I.D.: 3″ (75mm)

- Duty Cycle: 250A / 60% | 190A / 100%

- Weight: 15.43 lbs (without bundle/spool)

- Compatible Power Sources: P6

- Wire feed speed: up to 45.4 in/min

- Wire spool capacity: 3.3 lbs (on-board) or 33 lbs (external Polyfil-3)