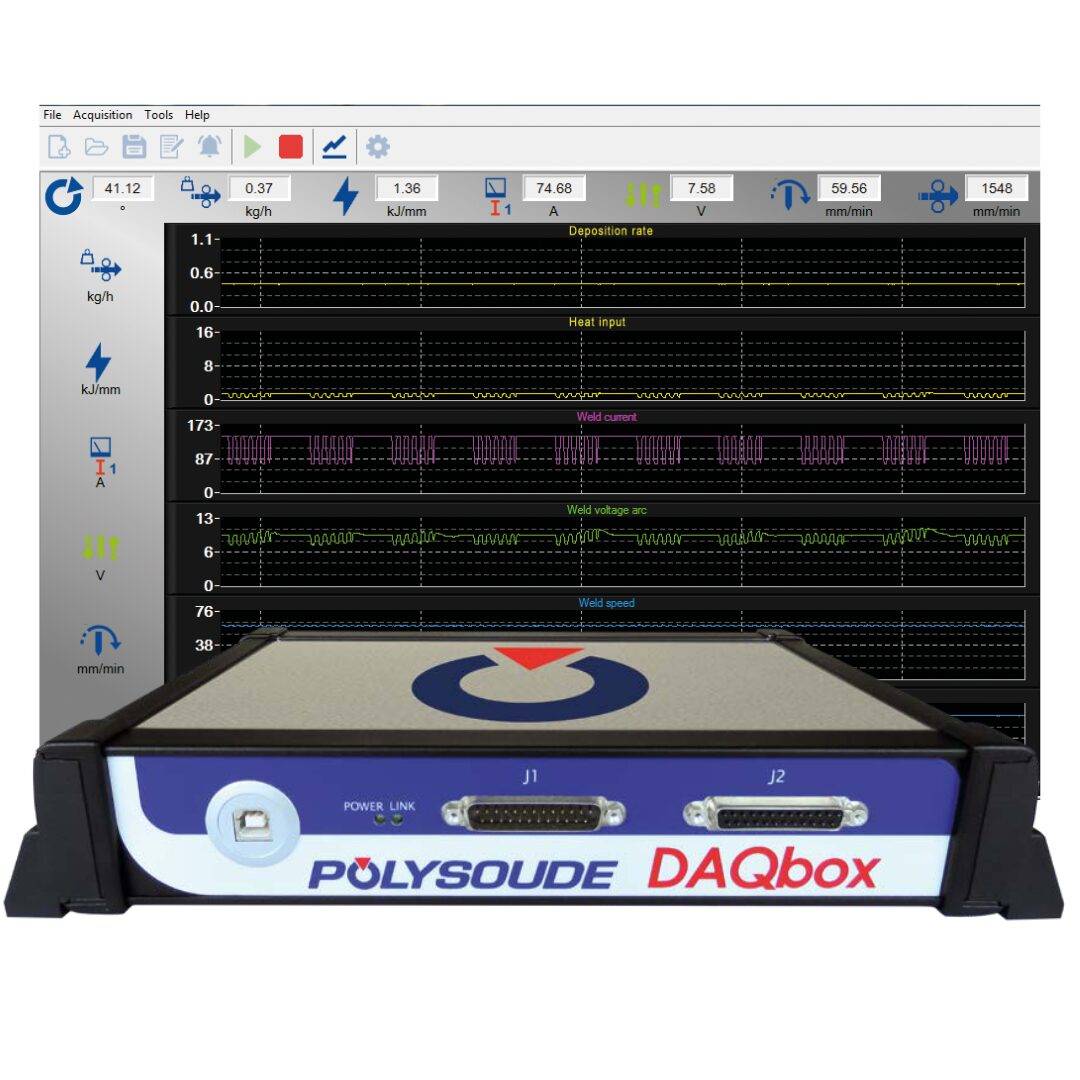

Tracking and real-time measurement for deposition rate & welding energy

The DAQbox is an advanced, USB-powered data acquisition system designed to simplify and enhance welding performance monitoring. Whether used as a standalone external module or integrated within a complete control unit, the DAQbox provides real-time visibility into essential welding parameters, helping operators maintain high productivity and consistent weld quality.

The DAQbox enables operators to monitor productivity in real time by tracking the deposition rate, welding energy, and the total number of welds completed each day. The system’s interface presents these values clearly through continuously updating graphs. These displays include deposition rate, heat input, weld current, arc voltage, weld speed, and wire speed, offering a comprehensive overview of the welding process as it unfolds.

To maintain a high level of consistency and traceability, the DAQbox incorporates several built-in quality control features. The system can automatically generate detailed welding reports in PDF format, allowing teams to document performance and verify results. It also supports passive or active alarms that can be customized for individual channels and defined sectors of the weld, ensuring that deviations are flagged immediately. Operators can select from eight different acquisition frequencies depending on the precision they require, and they may specify destination folders for stored data to keep project files organized and accessible.

The DAQbox is the ideal solution for welding operations seeking better control, improved quality, and enhanced productivity. With real-time monitoring, automated reporting, and effortless integration, it elevates any welding setup to a higher standard of performance.

Benefits and Features:

– Real-time productivity monitoring

– Configurable channel names

– Measurement type selected by the software

– Connection to computer via USB

– DAQbox power supply via USB (no need for a power pack)

– Intuitive interface, multi-lingual

– Adjustable passive or active alarms by channel and sector

– Choice of 8 acquisition frequencies

– Choice of destination folder for the saved files